Home> Company News> 6002rs Unleashed: Unraveling the Precision within Every Rotation

- AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Factory AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Worktime9:00-18:00

- Phone(Working Time)0531-85064681

- Phone(Nonworking Time)0531-85064680

- Fax0531-85064680

Introduction

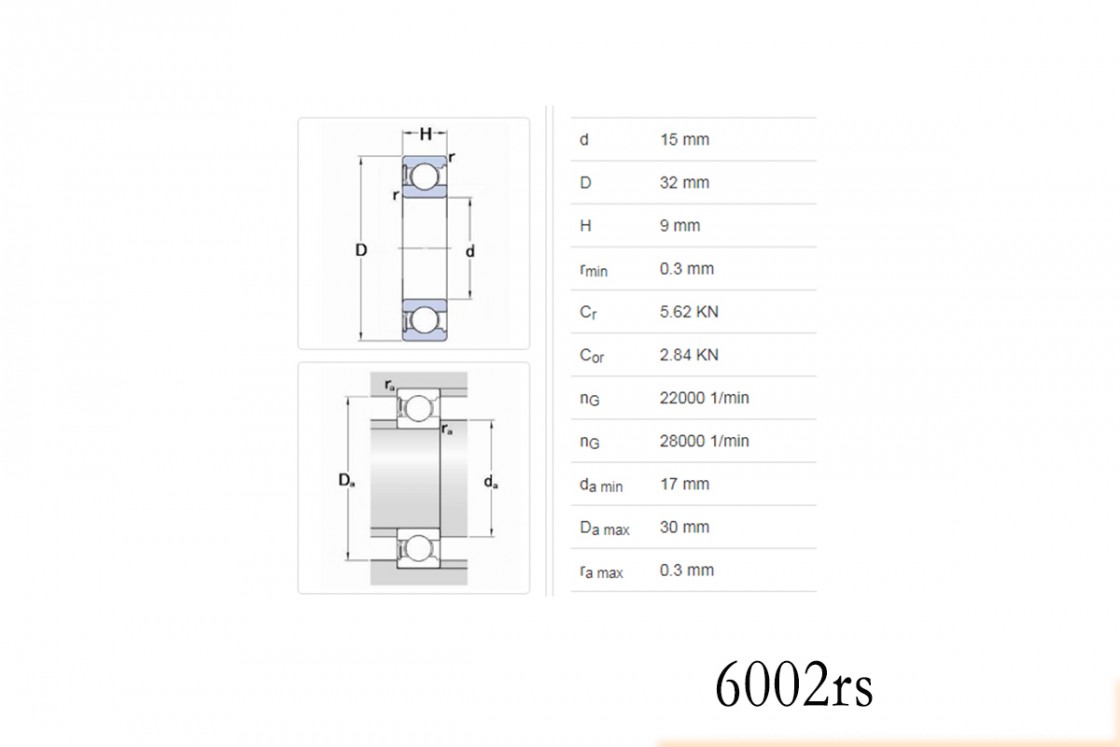

In the realm of precision engineering, the 6002RS double side sealed deep groove bearing ball stands as a testament to innovation and excellence. unveils the significance of the 6002RS bearing, a key component in rotating machinery where precision is not just a requirement but a necessity. As we delve into the intricacies of this bearing, the profound impact it has on every rotation becomes apparent, setting the stage for a comprehensive exploration of its design, engineering, applications, and maintenance.

Precision is the cornerstone of efficient machinery, and the 6002RS bearing plays a pivotal role in ensuring the smooth operation of various devices. As we unravel the layers of precision within every rotation, we'll gain insights into the anatomy of the 6002RS bearing, understanding its unique features and how they contribute to its exceptional performance. discover the engineering marvels hidden within the seemingly simple yet crucial 6002RS double side sealed deep groove bearing ball.

Anatomy of 6002RS Bearing

In the intricate world of bearings, the 6002RS stands out for its meticulously crafted design and structural elements that contribute to its unparalleled precision.

Structure and Design Elements

The 6002RS bearing boasts a sophisticated structure designed with precision engineering. Its core components include:

|

Inner and Outer Rings |

- The inner and outer rings provide the foundational support for the bearing. - Precision machining ensures a perfect fit, reducing friction and enhancing overall efficiency. |

|

Balls |

- The ball bearings inside the 6002RS contribute to its smooth rotation. - Made from high-quality materials, these balls ensure durability and consistent performance. |

|

Double Side Sealed Feature |

- One of the distinctive features of the 6002RS bearing is its double side sealed design. - This sealing mechanism acts as a protective barrier against contaminants, extending the bearing's lifespan and maintaining optimal functionality. |

|

Cage |

- The cage holds the balls in place, facilitating their movement and maintaining equal spacing. - A well-designed cage enhances the overall stability and longevity of the bearing.

|

Impact of Double Side Sealed Feature

The double side sealed feature of the 6002RS bearing plays a crucial role in preserving its precision and performance. The seals act as a barrier, preventing dust, moisture, and other contaminants from infiltrating the bearing. This not only ensures a cleaner operating environment but also protects the internal components from wear and damage.

The sealed design is particularly advantageous in applications where the bearing is exposed to harsh conditions or contaminants. Industries such as automotive, manufacturing, and machinery benefit significantly from this feature, as it contributes to the reliability and longevity of the bearing, even in demanding operational environments.

As we navigate through the intricacies of the 6002RS bearing's anatomy, it becomes evident that every component serves a purpose in enhancing precision and promoting efficient rotation. The meticulous design and double side sealed feature set the 6002RS apart, making it a cornerstone in the realm of deep groove ball bearings.

Precision Engineering at Its Core

In the intricate world of bearings, where precision is paramount, the 6002RS stands as a testament to the pinnacle of precision engineering.

Precision Engineering Techniques

Machining Excellence:

- Precision begins with the machining process. The inner and outer rings of the 6002RS bearing undergo meticulous machining to achieve dimensional accuracy.

- State-of-the-art machining technologies ensure that each component meets exact specifications, contributing to the bearing's overall precision.

Tight Tolerances:

- The manufacturing process involves adhering to tight tolerances to guarantee a perfect fit between components.

- Maintaining strict tolerances reduces clearance, minimizes friction, and enhances the bearing's responsiveness and accuracy.

Superior Materials:

- The choice of materials is crucial in precision engineering. The 6002RS bearing utilizes high-quality materials resistant to wear and corrosion.

- These materials ensure the longevity of the bearing, even in demanding conditions, while maintaining its precision over time.

Deep Groove Design and Technologies

Deep Groove Geometry:

- The deep groove design of the 6002RS allows for the distribution of loads across a larger surface area.

- This design enhances the bearing's ability to handle radial and axial loads with optimal efficiency, making it versatile in various applications.

Double Side Sealed Innovation:

- The double side sealed feature, a hallmark of the 6002RS, is a result of cutting-edge engineering.

- These seals not only provide protection against contaminants but also contribute to maintaining the precise functioning of the bearing, even in challenging environments.

|

Brand |

Material |

Sealing |

Precision Rating |

Load Capacity |

Operating Temperature |

Lubrication |

|

SKF |

High-Quality Steel |

Double Side Sealed |

ABEC-3 |

Radial and Axial Loads |

-40°C to +100°C |

Grease Lubrication (pre-filled) |

|

FAG |

Chrome Steel |

Double Side Sealed |

ABEC-1 |

Moderate |

-30°C to +120°C |

Grease Lubrication (pre-filled) |

|

NSK |

Stainless Steel |

Double Side Sealed |

ABEC-5 |

High |

-20°C to +120°C |

Grease Lubrication (pre-filled) |

|

NTN |

Carbon Chrome Steel |

Double Side Sealed |

ABEC-3 |

High |

-40°C to +120°C |

Grease Lubrication (pre-filled) |

As we unfold the applications across industries, we witness the **6002RS Double Side Sealed Deep Groove Bearing Ball** making its mark in the diverse tapestry of manufacturing, automotive, robotics, and beyond. Its adaptability, reliability, and contribution to efficiency position it as a key player in enhancing the performance of machinery across various sectors.

This table provides a quick comparison of 6002RS bearings from different brands, covering aspects like material, sealing, precision rating, load capacity, operating temperature, and lubrication. It can serve as a useful reference for those evaluating options from various manufacturers.

Applications Across Industries

In the realm of precision bearings, the 6002RS double side sealed deep groove bearing ball stands out as a versatile component with applications spanning across various industries. will delve into the wide array of industrial uses where the 6002RS bearing excels, unraveling its precision and reliability in different machinery and systems.

Industrial Machinery

One of the primary applications of the 6002RS bearing is in industrial machinery. Whether it be conveyor systems, manufacturing equipment, or assembly lines, these bearings play a crucial role in ensuring the smooth and efficient operation of machinery. The double side sealed feature provides an extra layer of protection against contaminants, making them ideal for demanding industrial environments.

Automotive Sector

In the automotive sector, precision is paramount, and the 6002RS bearing delivers. From wheel hubs to transmissions, these bearings contribute to the overall performance and safety of vehicles. The double side sealed design helps prevent water and debris ingress, maintaining the integrity of the bearing and prolonging its lifespan.

Electrical Appliances

The precision engineering of the 6002RS bearing finds its way into various electrical appliances. From electric motors to household appliances, these bearings provide reliable and quiet operation. The double side sealing ensures a dust-free environment, making them suitable for appliances where cleanliness is essential.

Aerospace Applications

In the aerospace industry, where precision and reliability are critical, the 6002RS bearing finds its place in various components. From control systems to landing gear mechanisms, these bearings contribute to the overall safety and efficiency of aerospace machinery.

Agricultural Machinery

Agricultural equipment operates in diverse and challenging environments. The 6002RS bearing's robust design and double side sealing make it well-suited for agricultural machinery such as tractors, combines, and seeding equipment. It withstands harsh conditions, ensuring optimal performance in the field.

Medical Equipment

Precision bearings play a crucial role in medical equipment, where accuracy and reliability are non-negotiable. The 6002RS bearing, with its double side sealing and precision engineering, finds applications in medical devices, imaging equipment, and other healthcare machinery.

In conclusion, the 6002RS bearing's versatility extends beyond conventional uses, making it a valuable component in a multitude of industries. Its precision engineering, coupled with the double side sealed feature, positions it as a reliable choice for various machinery and applications, contributing to the efficiency and performance of diverse industrial sectors.

Maintenance Guidelines

Importance of Maintenance

Before we explore the specific maintenance steps, it's essential to understand why maintenance is crucial for bearings. Regular maintenance not only extends the lifespan of the 6002RS bearing but also ensures consistent performance, reduces the risk of failures, and prevents unexpected downtime in various applications.

Lubrication Matters

|

Lubrication is the Lifeblood |

Proper lubrication is fundamental to bearing health. The 6002RS bearing, with its double side sealing, provides an extra layer of protection against contaminants. However, regular lubrication remains paramount. Utilize high-quality lubricants suitable for your specific application, and adhere to recommended intervals. |

|

Inspect and Replenish |

Regularly inspect the lubrication levels. If you notice any signs of contamination or reduced lubrication, address the issue promptly. Replenish the lubricant according to the manufacturer's recommendations, ensuring the bearing operates smoothly. |

|

Shielding Against Elements |

The double side sealed design of the 6002RS bearing offers excellent protection, but environmental factors can still impact performance. Regularly inspect the seals for any signs of wear, damage, or leakage. Replace seals promptly to maintain the integrity of the bearing. |

|

Cleanliness is Key |

Before performing any maintenance, ensure a clean working environment. Contaminants introduced during maintenance procedures can compromise the bearing's precision. Use proper cleaning agents and techniques to prevent debris from entering the bearing. |

Inspection Protocols

Routine Checks:

Implement routine inspections to detect potential issues before they escalate. Check for abnormal noise, vibrations, or temperature fluctuations during operation. Address any irregularities promptly to prevent further damage.

Alignment and Mounting:

Proper alignment and mounting are critical for bearing performance. Regularly check the alignment of the 6002RS bearing and ensure correct mounting procedures are followed. Misalignment can lead to premature wear and reduced efficiency.

Conclusion

In conclusion, the maintenance of 6002RS double side sealed deep groove bearings is a proactive approach to ensure prolonged efficiency and reliability. Regular lubrication, environmental considerations, and thorough inspections contribute to the optimal performance of these precision components across various applications. By following these maintenance guidelines, you can unlock the full potential of the 6002RS bearing and enjoy consistent, high-performance rotation in your machinery.

Advantages and Future Innovations

Introduction

In the intricate world of precision engineering, the 6002RS double side sealed deep groove bearing ball stands as a testament to excellence. As we delve into this segment, our focus is two-fold: first, we unravel the existing advantages that make 6002RS bearings a preferred choice, and second, we peer into the future, speculating on innovations that might shape the landscape of deep groove bearing ball technology.

Advantages of 6002RS Bearings

Enhanced Efficiency:

The 6002RS bearing, with its double side sealed feature, is at the forefront of efficiency in rotating machinery. The sealing mechanism not only protects against external contaminants but also minimizes frictional losses, ensuring smoother and more energy-efficient rotations.

Reduced Maintenance Requirements:

One of the distinctive features of 6002RS bearings is their sealed design, which reduces the need for frequent maintenance. The effective sealing prevents the ingress of dust, moisture, and other contaminants, leading to prolonged operational life and decreased maintenance costs.

Extended Lifespan:

Precision engineering in 6002RS bearings contributes to an extended lifespan. The robust construction and sealed design enhance durability, making these bearings a reliable and long-lasting component in various applications.

Versatility Across Industries:

The adaptability of 6002RS bearings spans across diverse industries. From automotive systems to manufacturing machinery, their versatility makes them integral components in a wide range of operational environments.

Future Innovations in Deep Groove Bearing Ball Technology

Advanced Materials Integration:

The future of deep groove bearing ball technology may witness the integration of advanced materials. Materials with enhanced wear resistance, increased load-carrying capacity, and heightened tolerance to extreme conditions could redefine the performance parameters of these bearings.

Smart Bearing Technology:

Anticipating the digital era, smart bearing technology might become a reality. Integration of sensors and monitoring capabilities directly into the bearing could provide real-time insights into its performance, enabling predictive maintenance and optimizing operational efficiency.

Nanotechnology Applications:

The precision required in bearing technology could benefit significantly from nanotechnology. The ability to manipulate materials at the nanoscale might lead to bearings with reduced friction, improved load capacities, and enhanced overall performance.

Eco-Friendly Bearing Solutions:

Environmental considerations may drive the development of eco-friendly bearing solutions. This could involve the use of bio-based lubricants, recyclable materials, and manufacturing processes with a reduced ecological footprint.

Conclusion

In conclusion, the 6002RS double side sealed deep groove bearing ball is not merely a component; it is a precision-engineered marvel that contributes to the efficiency and reliability of rotating machinery. Its existing advantages make it a preferred choice across industries, and the potential future innovations discussed here hint at an exciting evolution in bearing technology. As industries evolve and demands for efficiency heighten, the 6002RS bearing stands poised at the forefront, ready to unravel new dimensions of precision in every rotation.

FAQs: Common Questions About 6002RS Double Side Sealed Deep Groove Bearing Ball

Introduction

As we delve into the intricacies of the 6002RS double side sealed deep groove bearing ball, it's essential to address some common questions that often arise regarding its usage, features, and applications. we aim to provide comprehensive answers to frequently asked questions to enhance understanding and clarity.

What is a 6002RS bearing, and how does it differ from other bearings?

6002RS Bearing Overview:

The 6002RS bearing is a type of deep groove ball bearing designed with double side seals for enhanced protection against contaminants. It differs from other bearings in its sealing mechanism, which prevents the ingress of dust, moisture, and other particles, thereby prolonging its lifespan and maintaining optimal performance.

What are the advantages of using a 6002RS bearing?

Advantages of 6002RS Bearing:

- Enhanced Protection: The double side seals provide superior protection against contaminants, ensuring smooth and reliable operation in various environments.

- Reduced Maintenance: The effective sealing minimizes the need for frequent maintenance, saving time and resources.

- Extended Lifespan: The robust construction and sealed design contribute to an extended lifespan, making the 6002RS bearing a durable and reliable component.

What industries commonly use 6002RS bearings?

Industries Utilizing 6002RS Bearings:

6002RS bearings find applications across a wide range of industries, including automotive, manufacturing, agricultural, and industrial machinery. Their versatility and reliability make them integral components in various rotating machinery and systems.

How should I properly install and maintain a 6002RS bearing?

Installation and Maintenance Guidelines:

- Ensure proper alignment during installation to prevent misalignment and premature wear.

- Use appropriate lubricants and follow manufacturer recommendations for lubrication intervals.

- Regularly inspect the bearing for signs of wear or damage, and replace if necessary to prevent unexpected failures.

Can a 6002RS bearing withstand high-speed applications?

High-Speed Performance:

Yes, 6002RS bearings are designed to withstand high-speed applications. However, proper lubrication and maintenance are essential to ensure optimal performance and longevity, especially in high-speed environments.

Are there any potential challenges or limitations associated with 6002RS bearings?

Challenges and Limitations:

While 6002RS bearings offer numerous advantages, they may face challenges in extreme operating conditions or environments with high levels of contamination. Regular maintenance and monitoring can help mitigate these challenges and ensure continued performance.

Conclusion

In conclusion, the 6002RS double side sealed deep groove bearing ball is a versatile and reliable component widely used across industries for its enhanced protection, extended lifespan, and overall efficiency. By addressing common questions and providing comprehensive answers, we aim to facilitate a better understanding of this essential bearing type, empowering users to make informed decisions regarding its usage and maintenance.

232/500 KCW33+H32/500 SKF Spherical Roller Bearings

232/500 KCW33+H32/500 SKF Spherical Roller Bearings 23128-E1A-M FAG Spherical Roller Bearings

23128-E1A-M FAG Spherical Roller Bearings