Home> Company News> EuroCrafted Mastery: Decoding the Essence of 6202z Bearings

- AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Factory AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Worktime9:00-18:00

- Phone(Working Time)0531-85064681

- Phone(Nonworking Time)0531-85064680

- Fax0531-85064680

Introduction

Unveiling Precision Engineering

At the heart of the 6202Z bearing lies the artistry of precision engineering. Reveal how carefully designed and engineered are the structures of these bearings. Every nuance, from the choice of materials to the intricacy of the design, contributes to the precision that distinguishes 6202Z bearings.

Significance in Machinery Dynamics

Why is precision engineering significant in the realm of machinery? We explore how 6202Z bearings play a pivotal role in enhancing the dynamics of various machinery. From reducing friction to ensuring seamless operations, the precision embedded in these bearings becomes the cornerstone of machinery efficiency.

EuroCrafted Mastery Unveiled

EuroCrafted Mastery is not just a phrase; it's a commitment to excellence. unfolds the essence of European precision engineering and how it intertwines with the design philosophy of 6202Z bearings. The distinctive touch of European craftsmanship sets these bearings apart, making them a symbol of reliability and innovation.

Navigating the Exploration

As we navigate through this exploration, the stage is set for an in-depth journey into the various facets of 6202Z bearings. From their design intricacies to applications across diverse industries, we aim to unravel the secrets that make these bearings a paragon of precision and functionality.

Into the structural brilliance of 6202Z bearings, examine their applications across industries, scrutinize their performance metrics, and explore the influence of European precision engineering on their manufacturing. Each layer of information contributes to a comprehensive understanding of 6202Z ball bearings and their significance in the world of EuroCrafted Mastery.

Understanding 6202Z Bearings

Design Excellence: Unveiling the Blueprint

6202Z bearings are a testament to design excellence. The blueprint of these bearings is meticulously crafted to ensure optimal performance in various applications. The design takes into account factors such as load-bearing capacity, rotational speed, and the ability to withstand environmental conditions. Precision engineering is the guiding principle behind every curve and contour, ensuring these bearings meet the highest standards.

Structural Brilliance: Anatomy of 6202Z Bearings

Understanding the anatomy of 6202Z bearings is crucial to appreciating their functionality. The structural brilliance lies in the choice of materials, the arrangement of components, and the overall architecture. The composition of high-quality steel and advanced alloys ensures durability, while precision-machined components contribute to the smooth operation of these bearings. As we dissect the structure, it becomes evident how meticulous engineering leads to enhanced bearing performance.

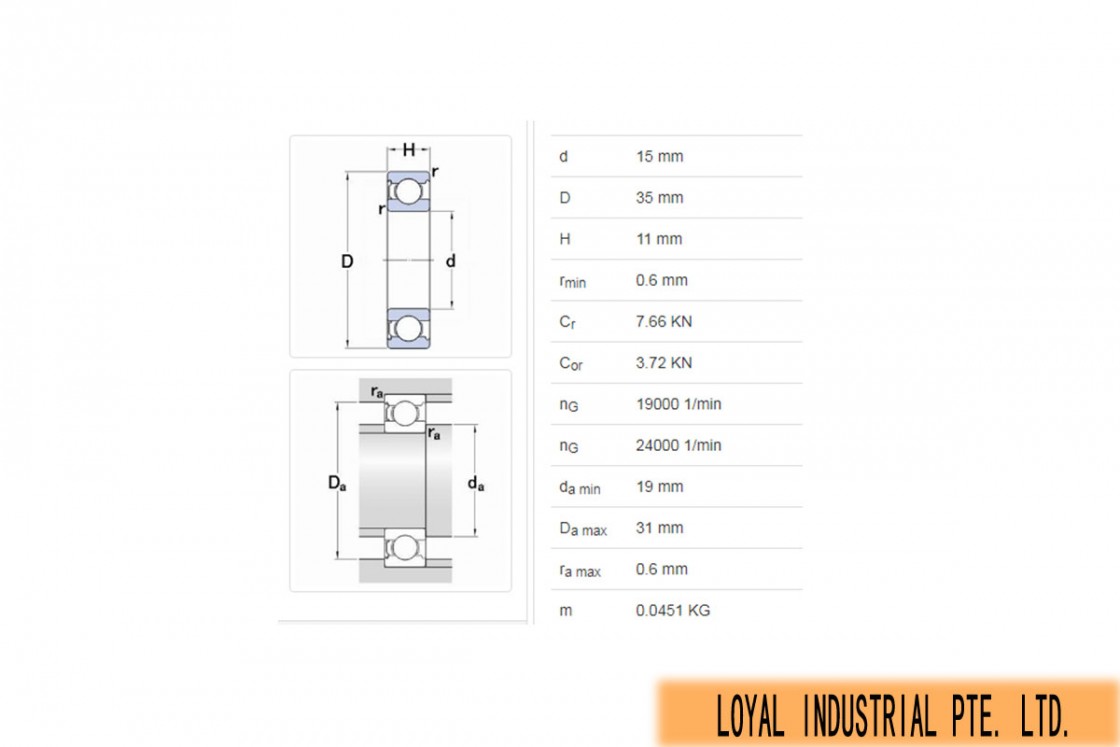

Key Features and Specifications: Setting Standards

What makes 6202Z bearings stand out in the market? This subsection focuses on highlighting the key features and specifications that define these bearings. From their exceptional radial load capacity to the ability to operate at high speeds, each specification is a testament to the precision and innovation embedded in their design. As we delve into specifics, we'll emphasize how these features contribute to the versatility of 6202Z bearings across various applications.

Precision Engineering in Action: Performance and Reliability

Precision engineering is not just a buzzword; it's a driving force behind the performance and reliability of 6202Z bearings. This part of the exploration scrutinizes the role of precision engineering in shaping the capabilities of these bearings. From minimizing friction to ensuring consistent and accurate rotational motion, the design intricacies influenced by European precision engineering elevate these bearings to unparalleled levels of performance and reliability.

As we unravel the nuances of 6202Z bearings, it becomes evident that understanding their design, structure, and the precision engineering principles governing them is fundamental to appreciating their significance. we'll further explore applications across industries, delve into performance metrics, and decode the essence of European precision in 6202Z ball bearings.

Applications Across Industries

As we journey deeper into the realm of 6202Z ball bearings, it's essential to explore the myriad applications that make these precision-engineered components indispensable across a spectrum of industries. Let's delve into the versatility and reliability of 6202Z bearings, examining their real-world applications and the transformative impact they bring to diverse sectors.

Versatility Unleashed: Diverse Industrial Applications

6202Z bearings find themselves at the heart of various industrial applications, contributing to the seamless operation of machinery in different sectors. Their adaptability and reliability make them a preferred choice, ensuring optimal performance in challenging environments. From manufacturing plants to automotive systems, the versatility of 6202Z bearings transcends boundaries, underscoring their significance in the industrial landscape.

Automotive Sector

In the automotive industry, 6202Z bearings play a crucial role in supporting radial and axial loads, contributing to the smooth functioning of wheels, transmissions, and differentials. The precision in their design ensures minimal friction, enhancing fuel efficiency and overall vehicle performance.

Manufacturing Machinery

In manufacturing processes, where precision is paramount, 6202Z bearings find applications in various machinery such as conveyor systems, gearboxes, and robotics. Their ability to withstand heavy loads and operate at high speeds positions them as vital components in optimizing production efficiency.

Showcasing Reliability in Action

To truly appreciate the impact of 6202Z bearings, let's delve into real-world examples that highlight their adaptability and reliability.

Conveyor Systems

In material handling systems, where continuous operation is critical, 6202Z bearings provide reliable support for conveyor belts. Their robust construction ensures consistent performance, reducing downtime and enhancing the overall efficiency of material handling processes.

HVAC Systems

Within heating, ventilation, and air conditioning (HVAC) systems, 6202Z bearings contribute to the smooth rotation of fans and blowers. Their ability to operate in diverse temperature conditions, coupled with precision engineering, ensures uninterrupted airflow and optimal climate control.

Enhancing Efficiency and Performance: The Impact on Industrial Settings

The influence of 6202Z bearings extends beyond merely supporting mechanical components. These bearings actively contribute to enhancing efficiency and performance in industrial settings. Their role in minimizing friction, reducing energy consumption, and ensuring precise rotational motion positions them as key contributors to overall operational excellence.

In conclusion, the applications of 6202Z ball bearings across industries underscore their versatility and reliability. From automotive engineering to manufacturing machinery, these bearings play a pivotal role in optimizing performance and contributing to the seamless operation of diverse systems.

|

Property |

SKF 6202Z Ball Bearing |

FAG 6202Z Ball Bearing |

NTN 6202Z Ball Bearing |

|

Brand |

SKF |

FAG |

NTN |

|

Material |

High-quality steel |

Chrome steel |

Stainless steel |

|

Precision Level |

ABEC-3 |

ABEC-1 |

ABEC-3 |

|

Cage Material |

Pressed steel |

Steel |

Stamped steel |

|

Seal Type |

Metal shields |

Metal shields |

Single metal shield |

|

Lubrication |

Grease |

Grease |

Grease |

|

Operating Temperature |

-40°C to 120°C |

-30°C to 110°C |

-40°C to 120°C |

|

Speed Rating |

30,000 RPM |

24,000 RPM |

28,000 RPM |

|

Load Capacity |

Radial and axial loads |

Radial loads |

Radial loads |

|

Application Focus |

General purpose |

Industrial machinery |

Electric motors |

Performance Metrics and Technical Specifications

In our exploration of 6202Z ball bearings, we shift our focus to the critical aspects that define their prowess—performance metrics and technical specifications. Understanding the intricacies of these factors is pivotal in appreciating the capabilities and reliability that 6202Z bearings bring to the forefront.

Unveiling Technical Excellence: The Specifications of 6202Z Bearings

Precision in Design

One of the hallmark features of 6202Z bearings lies in their precision design. The inner and outer ring diameters, ball size, and the width of the bearings are meticulously crafted to exact specifications. This precision ensures optimal load distribution, minimizing friction and contributing to the extended life and efficiency of the bearing.

Material Composition

6202Z bearings are crafted from high-quality materials, often including chrome steel or stainless steel. The selection of materials is a critical aspect of their design, ensuring resistance to corrosion, durability, and the ability to operate seamlessly even in challenging environmental conditions.

Sealing Mechanisms

The effectiveness of the sealing mechanisms is crucial for the protection of internal components from contaminants and moisture. Different variants of 6202Z bearings may feature single or double seals, each designed to provide an additional layer of defense against external elements, contributing to prolonged bearing life.

Performance Metrics: Understanding the Capabilities

Radial and Axial Loads

6202Z bearings exhibit exceptional load-bearing capabilities. Radial loads, acting perpendicular to the axis of rotation, and axial loads, parallel to the axis, are efficiently managed by these bearings. This versatility makes them suitable for a wide array of applications, from conveyor systems to electric motors.

Operating Speeds

Precision engineering allows 6202Z bearings to operate at high speeds without compromising on accuracy. The design considerations, lubrication mechanisms, and ball precision collectively contribute to the bearings' ability to maintain stability and reliability even under demanding conditions.

Noise and Vibration Levels

Reduced noise and vibration levels are inherent characteristics of well-crafted 6202Z bearings. The precision in design minimizes friction, resulting in smoother operation and quieter performance. This is particularly crucial in applications where noise reduction is a priority, such as in household appliances or precision machinery.

The Role of Precision Engineering in Performance

The technical specifications and performance metrics of 6202Z bearings underscore the significance of precision engineering in their design and manufacturing. Every aspect, from the choice of materials to the intricacies of the sealing mechanisms, is a testament to the commitment to technical excellence. Adhering to these specifications not only ensures optimal performance but also enhances the overall durability and reliability of 6202Z bearings.

European Precision Engineering Influence

In the realm of precision engineering, European standards have emerged as a guiding force, particularly in the manufacturing and quality assurance of bearings. delves into the profound influence of European precision engineering on 6202Z ball bearings, highlighting the innovative practices, global recognition, and superior performance associated with bearings crafted under these standards.

Examining European Precision Engineering Standards

Precision as a Cornerstone

European precision engineering places precision as a cornerstone in the manufacturing process of 6202Z bearings. The meticulous attention to detail ensures that each bearing adheres to stringent standards, resulting in products that consistently meet and exceed performance expectations.

Innovation in Manufacturing

European standards encourage continuous innovation in manufacturing techniques. This innovation not only enhances the efficiency of production but also contributes to the development of advanced features in 6202Z bearings. From materials selection to assembly, the European approach integrates cutting-edge technology to achieve optimal results.

Striving for Perfection

European precision engineering embodies a commitment to perfection. The pursuit of excellence in every phase of bearing production, from design conceptualization to the final product, sets a benchmark that resonates throughout the industry. 6202Z bearings, crafted under these principles, stand as exemplars of precision and reliability.

Setting Benchmarks in the Bearing Industry

Influence on Global Standards

European expertise significantly influences global standards in the bearing industry. The commitment to excellence and continuous improvement resonates with manufacturers worldwide, prompting the adoption of similar practices to elevate the quality of bearings produced across the globe.

Innovation Driving Recognition

Innovation is a driving force behind the global recognition of European-crafted 6202Z bearings. The bearings not only meet the demands of various applications but also showcase features that set them apart. The global bearing industry acknowledges the impact of European innovation in pushing the boundaries of what is achievable.

Reliability on a Global Scale

The reputation of European-crafted 6202Z bearings extends far beyond regional borders. These bearings are recognized globally for their reliability, longevity, and consistent performance. Industries worldwide trust in the reliability of European precision engineering, making these bearings a preferred choice across diverse applications.

Conclusion: A Global Legacy of Precision Excellence

In conclusion, the influence of European precision engineering on 6202Z bearings is a testament to a global legacy of precision excellence. The meticulous standards, innovative practices, and global recognition contribute to bearings that not only meet the needs of diverse industries but also set a standard for excellence.

Quality Assurance and Reliability

Unveiling the EuroCrafted Mastery

Introduction

Welcome to the realm where precision meets assurance, and reliability becomes an inherent trait. we unravel the intricate tapestry of EuroCrafted Mastery, specifically focusing on the robust quality assurance measures that underpin European bearing manufacturing, and how these measures are intertwined with the durability, reliability, and longevity of the iconic 6202Z ball bearings.

Quality Assurance Measures in European Bearing Manufacturing

Stringent Standards

European bearing manufacturing operates under the umbrella of stringent quality standards. Each step of the production process is meticulously governed by these standards, ensuring that every 6202Z bearing that rolls off the production line adheres to the highest benchmarks of quality.

Advanced Testing Protocols

Quality assurance is not a mere formality; it's a comprehensive process that involves advanced testing protocols. European bearing manufacturers subject 6202Z bearings to a battery of tests, including stress tests, load tests, and environmental simulations. This ensures that the bearings can withstand diverse operational conditions with unwavering stability.

Traceability and Transparency

EuroCrafted Mastery places a premium on traceability and transparency in the manufacturing process. Each component of a 6202Z bearing can be traced back to its origin, providing unparalleled transparency. This traceability not only enhances accountability but also ensures that every bearing meets the exacting standards set by European precision engineering.

Precision Engineering for Durability and Reliability

|

Integral Role of Precision |

Precision engineering is not a mere buzzword; it's the backbone of EuroCrafted Mastery. The design and manufacturing of 6202Z bearings are imbued with precision at every step. This meticulous approach guarantees the integrity of the bearings, making them capable of delivering consistent and reliable performance throughout their operational life. |

|

Durability Beyond Expectations |

Durability is not just a feature; it's an expectation. European precision engineering ensures that 6202Z bearings surpass conventional expectations of durability. Whether in high-speed applications or heavy-load environments, these bearings maintain their structural integrity, contributing to the overall efficiency of machinery. |

|

Reliability: A EuroCrafted Signature |

Reliability is the hallmark of EuroCrafted 6202Z bearings. Industries worldwide rely on the consistency and predictability of these bearings, knowing that they are crafted under the watchful eye of precision engineering. The reliability of EuroCrafted bearings is not just a characteristic; it's a promise fulfilled. |

Commitment to Continuous Improvement

Driving Excellence

EuroCrafted Mastery is not static; it's a journey of continuous improvement. The commitment to quality is not a one-time effort but an ongoing pursuit of excellence. European bearing manufacturers continually refine their processes, integrate the latest technological advancements, and adapt to emerging industry trends.

Conclusion: The EuroCrafted Seal of Quality

In conclusion, EuroCrafted Mastery in bearing manufacturing sets a standard that transcends the ordinary. The rigorous quality assurance measures, coupled with precision engineering, define the 6202Z bearings as not just components but as a testament to European excellence.

Conclusion

Unveiling the Essence of EuroCrafted Mastery

Recapitulating the Precision Journey

In our journey through the intricacies of 6202Z bearings within the realm of EuroCrafted Mastery, we've delved into the precision engineering that defines these bearings. From their design to the manufacturing process, precision has been the guiding force behind the creation of 6202Z bearings.

European Influence: A Pinnacle of Excellence

The exploration has underscored the profound influence of European precision engineering on the very DNA of 6202Z ball bearings. European standards and expertise stand as pillars, elevating these bearings to a pinnacle of excellence in the global market.

Applications Across Industries

As we navigated the diverse industrial landscape, it became evident that 6202Z bearings aren't just components; they are catalysts driving efficiency, performance, and reliability across various sectors. Their adaptability and reliability make them indispensable in machinery and systems worldwide.

Key Insights and Findings

Precision at Every Turn

Precision isn't just a feature; it's the defining characteristic of 6202Z bearings. From the microscopic dimensions of the components to the macro-level performance in real-world applications, precision engineering leaves an indelible mark on every facet of these bearings.

European Craftsmanship

EuroCrafted Mastery isn't a term; it's a testament to the craftsmanship embedded in every 6202Z bearing. The European touch goes beyond manufacturing – it's a commitment to quality, innovation, and setting benchmarks that reverberate throughout the bearing industry.

Driving Efficiency and Performance

6202Z bearings, crafted under the influence of European precision engineering, emerge as drivers of efficiency and performance. Industries relying on these bearings witness not just operational stability but enhanced productivity and longevity, thanks to the meticulous design and manufacturing.

Reinforcing the Significance

Beyond Components: Essential Elements

In conclusion, 6202Z bearings cease to be mere components; they are essential elements that embody the precision, craftsmanship, and reliability championed by European engineering. The exploration underscores their crucial role in the machinery and systems that power diverse industries.

A Global Standard of Reliability

As we close the chapter on EuroCrafted Mastery and 6202Z bearings, it's imperative to recognize them as a global standard of reliability. Their influence spans continents, and their reputation precedes them, making them a trusted choice in applications where precision and performance are non-negotiable.

Final Thoughts

In unraveling the intricacies of 6202Z bearings, we've witnessed more than the unveiling of a product; it's been a journey into the heart of European Precision Engineering. From the manufacturing floor to the far reaches of industrial applications, the essence of EuroCrafted Mastery shines through, leaving an indomitable mark on the world of ball bearings.

FAQs: Common Questions About 6202Z Bearings

What Sets 6202Z Bearings Apart in the Market?

6202Z bearings stand out in the market due to their precision engineering. Every component is meticulously crafted to meet European standards, ensuring unparalleled reliability and performance.

How Does European Precision Engineering Influence 6202Z Bearings?

European Precision Engineering is the cornerstone of 6202Z bearings. The influence extends from design to manufacturing, setting a global benchmark for quality, durability, and precision.

What Industrial Applications Are Ideal for 6202Z Bearings?

6202Z bearings find their place in diverse industrial applications, from machinery to systems requiring high-speed, accuracy, and reliability. Industries such as automotive, aerospace, and manufacturing benefit from their adaptability.

Are 6202Z Bearings Suitable for High-Speed Operations?

Yes, 6202Z bearings are engineered to operate at high speeds without compromising accuracy. The design and composition minimize friction, ensuring smooth and efficient performance even under demanding conditions.

What Technical Specifications Should Be Considered?

Key technical specifications include dimensions, load capacity, material composition, and precision ratings. Understanding these specifications is crucial for selecting the right bearing for specific applications.

How Does Quality Assurance Ensure the Reliability of 6202Z Bearings?

European manufacturing incorporates stringent quality assurance measures. From raw material inspection to final product testing, each step adheres to high standards, guaranteeing the reliability and longevity of 6202Z bearings.

Can 6202Z Bearings Withstand Harsh Environmental Conditions?

Yes, the design and materials used in 6202Z bearings make them resilient in challenging environments. They exhibit resistance to corrosion, temperature variations, and other environmental factors.

In wrapping up our FAQs session on 6202Z bearings, it's evident that these precision-engineered components are not only a product but a testament to European Precision Engineering. The common questions addressed here provide a comprehensive understanding of what sets 6202Z bearings apart and how they excel in diverse industrial landscapes.

232/500 KCW33+H32/500 SKF Spherical Roller Bearings

232/500 KCW33+H32/500 SKF Spherical Roller Bearings 23128-E1A-M FAG Spherical Roller Bearings

23128-E1A-M FAG Spherical Roller Bearings