Home> Company News> Efficiency Redefined: Cylindrical Roller Bearings Explored

- AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Factory AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Worktime9:00-18:00

- Phone(Working Time)0531-85064681

- Phone(Nonworking Time)0531-85064680

- Fax0531-85064680

Introduction

In the realm of machinery and industrial applications, efficiency stands as a cornerstone of optimal performance and productivity. At the heart of many mechanical systems lie Cylindrical Roller Bearings (CRBs), robust components engineered to redefine efficiency and reliability in various sectors.

Importance of Efficiency in Machinery

Efficiency serves as a driving force behind advancements in machinery design and operation. In today's competitive landscape, industries strive to maximize output while minimizing resource consumption, making efficiency a paramount consideration in engineering decisions.

Definition and Significance of Cylindrical Roller Bearings (CRBs)

Cylindrical Roller Bearings, often abbreviated as CRBs, represent a critical class of rolling element bearings designed to facilitate smooth and precise motion in machinery. These bearings feature cylindrical rollers with high radial load capacity, making them ideal for applications requiring support for heavy radial loads.

CRBs play a pivotal role in ensuring the smooth operation of various mechanical systems, ranging from automotive transmissions and electric motors to industrial gearboxes and machine tools. Their ability to handle both radial and axial loads with minimal friction contributes to the overall efficiency and longevity of machinery.

Conclusion

In conclusion, the exploration of Cylindrical Roller Bearings sheds light on their significance in enhancing efficiency and reliability across diverse industrial sectors. As integral components of modern machinery, CRBs exemplify innovation and excellence, driving performance optimization and redefining efficiency standards in the dynamic landscape of industrial engineering.

Understanding Cylindrical Roller Bearings

Cylindrical Roller Bearings (CRBs) represent a cornerstone in the domain of mechanical engineering, offering robust support and precise motion control in a variety of applications. Let's delve into the intricacies of CRBs, exploring their structure, capabilities, and distinguishing features.

|

Aspect |

Description |

|

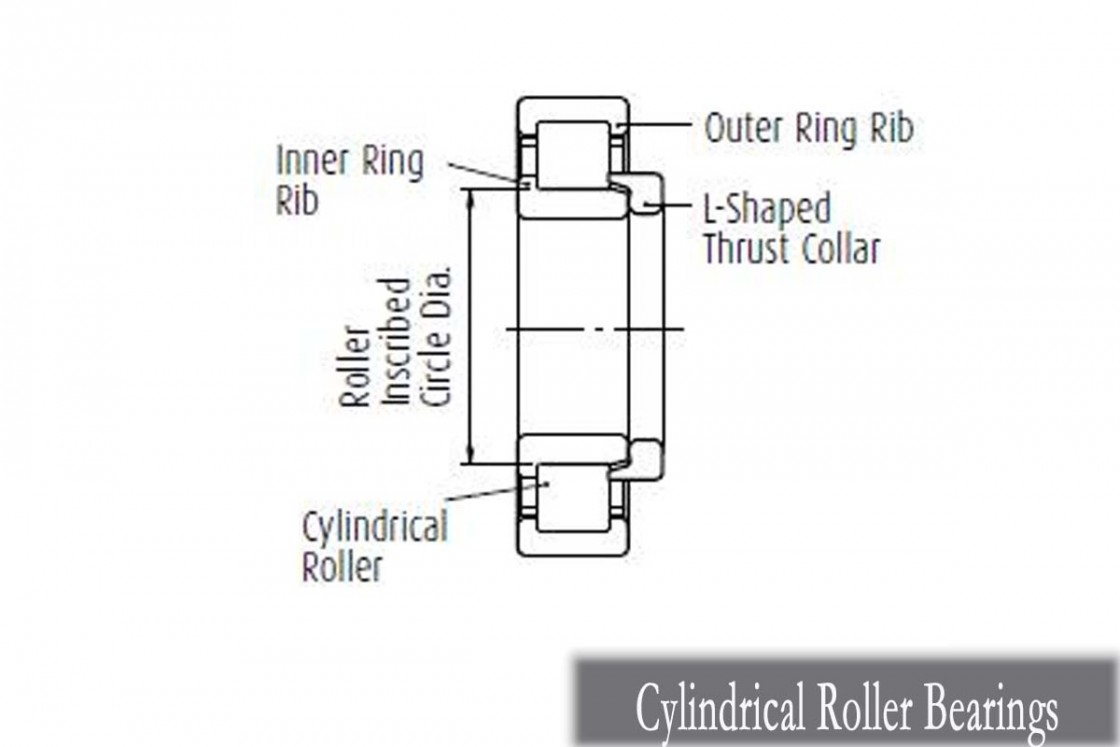

Structure and Components |

At the heart of CRBs lies a sophisticated arrangement of components meticulously designed to withstand high radial loads and ensure smooth operation. |

|

|

- Inner and outer rings provide structural integrity and guide the cylindrical rollers along their designated paths. |

|

|

- Cylindrical rollers distribute loads evenly across their surfaces, minimizing friction and wear. |

|

|

- Cages maintain proper spacing and alignment of the rollers, facilitating smooth rotation and preventing contact between adjacent rollers. |

|

|

- Raceways on the inner and outer rings provide contact surfaces where the rollers engage, enabling efficient load transmission and reducing stress concentrations. |

|

Comparison with Other Bearing Types |

CRBs stand out for their ability to handle substantial radial loads while accommodating misalignment. |

|

|

- Unlike ball bearings, CRBs are engineered for durability and reliability in environments where radial loads predominate. |

|

|

- CRBs offer distinct advantages over spherical roller bearings and tapered roller bearings in terms of precision performance and rigidity. |

|

Key Features and Characteristics |

CRBs boast high rigidity and precision performance, making them suitable for applications requiring tight tolerances and minimal deflection. |

|

|

- They exhibit low friction and wear characteristics, contributing to extended service life and reduced maintenance requirements. |

In conclusion, Cylindrical Roller Bearings emerge as versatile and reliable components essential for achieving efficiency and performance excellence in machinery and mechanical systems. Their robust structure, coupled with exceptional load-carrying capabilities and precision performance, makes them indispensable across diverse industrial sectors.

Anatomy and Design Features of Cylindrical Roller Bearings

Cylindrical Roller Bearings (CRBs) represent a pinnacle of engineering ingenuity, characterized by their intricate design and impeccable functionality. Let's delve into the anatomy and design features that underpin the exceptional performance of CRBs.

Cylindrical Shape for Optimal Load Distribution

At the core of CRBs lie cylindrical rollers meticulously engineered to distribute radial loads with unparalleled efficiency. The cylindrical shape of these rollers allows for a larger contact area with the raceways, enabling the bearings to withstand substantial radial loads while minimizing friction and heat generation. This design feature ensures smooth operation and prolonged service life even under demanding operating conditions.

Cage Designs for Enhanced Stability

Cages play a critical role in CRBs by maintaining the proper spacing and alignment of the cylindrical rollers. They prevent contact between adjacent rollers, thereby reducing friction and wear. Additionally, cage designs are optimized to facilitate smooth rotation and ensure uniform load distribution across the bearing surfaces. The materials used in cage construction are carefully selected to withstand high temperatures and corrosive environments, further enhancing the stability and longevity of the bearings.

Significance of Clearance Adjustment and Lubrication Systems

Proper clearance adjustment is paramount in optimizing the performance and longevity of CRBs. Clearance adjustment involves controlling the internal play between the rollers and raceways, ensuring optimal preload and minimizing excessive vibration or noise during operation. Additionally, effective lubrication systems are essential for reducing friction, dissipating heat, and preventing premature wear of critical components. Proper lubrication not only enhances the efficiency of CRBs but also extends their service life, ultimately reducing maintenance costs and downtime.

In conclusion, the anatomy and design features of Cylindrical Roller Bearings exemplify precision engineering at its finest. From the cylindrical shape of the rollers to the intricacies of cage designs and lubrication systems, every aspect is meticulously crafted to deliver optimal performance, efficiency, and reliability in diverse industrial applications.

Applications and Performance Characteristics of Cylindrical Roller Bearings

Cylindrical Roller Bearings (CRBs) find widespread applications across various industries and machinery, owing to their exceptional performance characteristics and versatility. Let's delve into the diverse applications and performance attributes of CRBs:

Versatile Applications in Industries:

CRBs play a pivotal role in numerous industries, including automotive, railway, and power generation sectors. In the automotive industry, CRBs are utilized in vehicle transmissions, wheel hubs, and engine components. Railway systems rely on CRBs for smooth operation of locomotives, railcars, and signaling systems. Additionally, CRBs are integral components in power generation equipment such as turbines, generators, and pumps.

Performance Characteristics:

CRBs exhibit exceptional performance characteristics under various operating conditions, ensuring reliable and efficient machinery operation. They excel in high-speed applications, maintaining stable performance even at elevated rotational speeds. Moreover, CRBs demonstrate resilience to extreme temperatures, maintaining their functionality in both hot and cold environments. Their ability to distribute loads evenly allows them to handle high radial loads with precision, ensuring optimal performance and longevity.

Benefits and Case Studies:

The adoption of CRBs offers significant benefits in terms of equipment efficiency, friction reduction, and reliability enhancement. Case studies showcase real-world scenarios where CRBs have led to tangible improvements in machinery performance. For instance, in automotive manufacturing plants, the integration of CRBs in conveyor systems has resulted in smoother material handling processes, leading to increased productivity and reduced downtime. Similarly, in power generation facilities, the implementation of CRBs in turbine assemblies has contributed to enhanced operational efficiency and extended service life.

Conclusion:

In conclusion, the widespread adoption of Cylindrical Roller Bearings across diverse industries underscores their indispensable role in optimizing machinery performance and efficiency. With their versatile applications and robust performance characteristics, CRBs continue to redefine efficiency standards, driving innovation and advancement in various sectors.

|

Brand |

SKF |

FAG |

NSK |

NTN |

|

Structure |

SKF cylindrical roller bearings typically consist of an inner ring, outer ring, cylindrical rollers, and cage. |

FAG cylindrical roller bearings are designed with an inner ring, outer ring, cylindrical rollers, and cage assembly. |

NSK cylindrical roller bearings feature an inner ring, outer ring, cylindrical rollers, and cage for optimized performance. |

NTN cylindrical roller bearings comprise an inner ring, outer ring, cylindrical rollers, and cage to ensure durability and reliability. |

|

Materials |

SKF often uses high-quality steel for its cylindrical roller bearings, ensuring excellent durability and reliability. |

FAG utilizes premium-grade materials in the manufacturing of its cylindrical roller bearings, ensuring superior performance and longevity. |

NSK employs advanced materials and heat treatment techniques to enhance the strength and durability of its cylindrical roller bearings. |

NTN employs stringent quality control measures to ensure the use of high-grade materials in its cylindrical roller bearings, resulting in exceptional performance and reliability. |

|

Precision |

SKF cylindrical roller bearings are known for their precision engineering, providing high accuracy and smooth operation in various applications. |

FAG cylindrical roller bearings are renowned for their precision manufacturing, offering excellent precision and reliability in demanding environments. |

NSK cylindrical roller bearings are manufactured to the highest precision standards, delivering consistent performance and reliability in critical applications. |

NTN cylindrical roller bearings are precision-engineered for superior accuracy and performance, meeting the demands of diverse industries. |

|

Sealing Solutions |

SKF offers a range of sealing solutions for its cylindrical roller bearings, including contact seals, non-contact seals, and labyrinth seals, providing options for different operating conditions. |

FAG provides various sealing solutions for its cylindrical roller bearings, ensuring effective protection against contaminants and extending bearing service life. |

NSK offers a comprehensive lineup of sealing solutions for its cylindrical roller bearings, including non-contact, contact, and low-friction seals, catering to diverse application requirements. |

NTN provides a variety of sealing options for its cylindrical roller bearings, including single lip seals, double lip seals, and integral seals, enhancing bearing performance and longevity. |

|

Application Range |

SKF cylindrical roller bearings are widely used in automotive, industrial machinery, and heavy equipment applications, offering reliable performance and durability. |

FAG cylindrical roller bearings find applications in automotive, aerospace, and industrial sectors, providing superior performance and longevity in challenging environments. |

NSK cylindrical roller bearings are utilized in automotive, manufacturing, and construction machinery, offering precision and reliability in demanding conditions. |

NTN cylindrical roller bearings are employed in automotive, railway, and power generation applications, delivering exceptional performance and reliability in diverse operating environments. |

Proper Installation Procedures

When it comes to installing Cylindrical Roller Bearings (CRBs), following proper procedures is crucial to ensure optimal performance and longevity. Here are some essential guidelines:

Shaft and Housing Considerations: Before installation, ensure that the shaft and housing are clean, free from any debris, and properly aligned. Any misalignment can lead to premature wear and reduced bearing lifespan.

Clearance Adjustment: Proper clearance adjustment is essential for CRBs to operate smoothly. Check the manufacturer's specifications for the recommended clearance values and adjust as necessary during installation.

Alignment Techniques: Use precision alignment tools to align the shaft and housing accurately. Misalignment can cause excessive loads on the bearings, leading to premature failure. Proper alignment ensures even distribution of loads and extends bearing life.

Regular Maintenance Schedules

Implementing regular maintenance schedules is vital for monitoring the condition of CRBs and detecting any early signs of wear or damage. Here's what you should include in your maintenance routine:

Visual Inspection: Regularly inspect CRBs for signs of wear, damage, or corrosion. Look for any abnormal noise, vibration, or overheating during operation, as these could indicate potential issues.

Greasing and Lubrication: Follow the manufacturer's recommendations for greasing intervals and lubrication methods. Proper lubrication is essential for reducing friction, preventing premature wear, and ensuring smooth operation.

Condition Monitoring: Implement condition monitoring techniques, such as vibration analysis or thermography, to detect any abnormalities in the bearing operation. Early detection of issues allows for timely maintenance and prevents costly downtime.

Selecting Appropriate Lubricants

Choosing the right lubricants and lubrication methods is crucial for optimizing CRB performance and extending service life. Consider the following factors:

Operating Conditions: Select lubricants suitable for the operating conditions of the application, including temperature, speed, and load. High-temperature environments may require specialized high-temperature grease, while high-speed applications may benefit from low-viscosity lubricants.

Compatibility: Ensure compatibility between the lubricant and the materials used in the bearing and surrounding components. Incompatible lubricants can lead to chemical reactions, causing damage to the bearings.

Lubrication Methods: Choose appropriate lubrication methods, such as manual greasing, centralized lubrication systems, or automatic lubricators, based on the application requirements and accessibility of the bearings.

In conclusion, adhering to proper installation procedures, implementing regular maintenance schedules, and selecting appropriate lubricants are essential best practices for maximizing the efficiency and longevity of Cylindrical Roller Bearings. By following these guidelines, you can ensure optimal performance and reliability of your machinery and equipment.

Recent Advancements in CRB Technology

In recent years, the field of Cylindrical Roller Bearings (CRBs) has seen significant advancements, revolutionizing the efficiency and performance of various industrial applications. Let's explore some of the key developments:

|

Aspect |

Description |

|

Improved Materials |

Manufacturers are focusing on developing advanced materials such as high-performance alloys, ceramics, and advanced polymers to enhance the strength, durability, and resistance to wear and fatigue of CRBs. |

|

Advanced Coatings |

Advanced coatings, including nanocoatings, diamond-like carbon (DLC) coatings, and various surface treatments, are applied to CRB surfaces to reduce friction, minimize wear, and extend the service life of bearings. |

|

Sealing Solutions |

Enhanced sealing solutions, such as advanced labyrinth seals, lip seals, and innovative sealing materials, are developed to improve contamination resistance and sealing effectiveness, thereby prolonging the service life of CRBs. |

Integration of Sensor Technology

An emerging trend in CRB technology is the integration of sensor technology for condition monitoring and predictive maintenance. Sensors embedded within the bearings enable real-time monitoring of operating conditions, including temperature, vibration, and lubrication status. This proactive approach allows for early detection of potential issues, such as bearing wear or lubrication breakdown, enabling timely maintenance interventions and preventing costly unplanned downtime.

Future Developments and Implications

Looking ahead, the future of CRBs holds promising opportunities for further advancements and innovations. Potential developments include:

Smart Bearings: The integration of artificial intelligence (AI) and machine learning algorithms into CRBs, enabling predictive analytics and proactive maintenance strategies based on real-time data analysis.

Advanced Lubrication Systems: Development of advanced lubrication systems, such as self-lubricating bearings and smart lubrication technologies, to optimize lubricant distribution and enhance the efficiency and reliability of CRBs.

Industry 4.0 Integration: Integration of CRB technology with Industry 4.0 principles, including connectivity, automation, and data exchange, to create intelligent bearing systems capable of self-monitoring, self-diagnosis, and autonomous decision-making.

In conclusion, the advancements and innovations in Cylindrical Roller Bearings are reshaping the landscape of industrial machinery and equipment. With ongoing research and development efforts, CRBs are poised to redefine efficiency, performance, and reliability in a wide range of applications, driving productivity and competitiveness in the global market.

Conclusion

In conclusion, the exploration of Cylindrical Roller Bearings (CRBs) has provided valuable insights into their anatomy, design, and wide-ranging applications across various industries. Throughout this discussion, we have emphasized the pivotal role that CRBs play in redefining efficiency in mechanical systems and elevating equipment performance and reliability to new heights.

Anatomy and Design: We have delved into the intricate structure of CRBs, highlighting their key components such as the inner and outer rings, cylindrical rollers, cages, and raceways. Understanding the design features of CRBs is essential for appreciating their ability to withstand high radial loads and maintain smooth operation in diverse operating conditions.

Applications: From automotive and railway systems to power generation and industrial machinery, CRBs find extensive use in a multitude of applications where efficiency and reliability are paramount. Their ability to handle high radial loads while accommodating misalignment makes them indispensable in modern mechanical systems.

Redefining Efficiency: CRBs serve as a cornerstone in the quest for efficiency gains in mechanical systems. By minimizing friction, reducing wear, and enhancing load-carrying capacity, CRBs contribute significantly to optimizing the performance of machinery and equipment, thereby improving productivity and reducing downtime.

Call to Action: As we conclude our exploration of CRBs, we extend a call to action to industry professionals to harness the power of CRB technology. By embracing CRBs and leveraging their capabilities, mechanical systems can achieve unprecedented levels of efficiency, productivity, and longevity. It is imperative for stakeholders to collaborate and innovate, driving forward the adoption of CRBs and realizing the full potential of these remarkable components.

In essence, Cylindrical Roller Bearings stand as a symbol of efficiency redefined, transforming the landscape of mechanical engineering and paving the way for a future where performance knows no bounds. Let us embrace this technology and embark on a journey towards a more efficient and sustainable future.

Frequently Asked Questions (FAQs) About Cylindrical Roller Bearings

What are Cylindrical Roller Bearings (CRBs)?

Cylindrical Roller Bearings (CRBs) are precision-engineered mechanical components designed to facilitate smooth rotational motion between two mating parts, typically a shaft and a housing. These bearings consist of cylindrical rollers held in place by inner and outer rings, with a cage or retainer to maintain proper roller alignment.

How do Cylindrical Roller Bearings work?

CRBs operate by distributing radial loads evenly across the cylindrical rollers, which roll along the raceways of the inner and outer rings. This design enables CRBs to handle high radial loads while maintaining alignment, making them suitable for various industrial applications.

What are the advantages of using Cylindrical Roller Bearings?

One of the primary advantages of CRBs is their ability to accommodate high radial loads with minimal friction. They also have a high radial rigidity, which helps maintain shaft alignment and prevents excessive deflection under load. Additionally, CRBs can withstand some axial loads and, in certain configurations, can accommodate misalignment.

What factors should be considered when selecting Cylindrical Roller Bearings?

When choosing CRBs for a specific application, factors such as load capacity, speed, temperature range, lubrication requirements, and environmental conditions must be taken into account. It's essential to select the appropriate bearing size, type, and configuration to ensure optimal performance and reliability.

How do you install and maintain Cylindrical Roller Bearings?

Proper installation is crucial for maximizing the performance and service life of CRBs. This involves ensuring correct shaft and housing fits, proper clearance adjustment, and alignment techniques. Regular maintenance, including lubrication, inspection for signs of wear or damage, and timely replacement when necessary, is also essential to keep CRBs operating efficiently.

What are common applications of Cylindrical Roller Bearings?

CRBs are widely used in various industries, including automotive, aerospace, industrial machinery, power generation, and more. They are commonly found in applications such as electric motors, pumps, gearboxes, conveyor systems, and machine tools, where high radial loads and precision motion control are required.

How do you troubleshoot common issues with Cylindrical Roller Bearings?

Common problems with CRBs include excessive noise, vibration, heat generation, and premature failure. Troubleshooting these issues often involves inspecting for misalignment, inadequate lubrication, contamination, or damage to the bearing components. Addressing these issues promptly can help prevent costly downtime and equipment failure.

232/500 KCW33+H32/500 SKF Spherical Roller Bearings

232/500 KCW33+H32/500 SKF Spherical Roller Bearings 23128-E1A-M FAG Spherical Roller Bearings

23128-E1A-M FAG Spherical Roller Bearings