Home> Company News> Mastering Performance: The Evolution of 6206RS 30x62x16 Sealed Ball Bearings

- AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Factory AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Worktime9:00-18:00

- Phone(Working Time)0531-85064681

- Phone(Nonworking Time)0531-85064680

- Fax0531-85064680

Introduction

In the realm of mechanical engineering, the significance of 6206RS 30x62x16 Sealed Ball Bearings cannot be overstated. These precision components serve as the cornerstone of countless industrial applications, facilitating smooth motion and efficient power transmission. As we delve into the evolution of 6206RS bearings, it becomes evident that their development has been pivotal in advancing various technologies across diverse industries.

The journey of 6206RS bearings traces back to the fundamental need for reliable and high-performance components in machinery. Over time, as industrial demands evolved and technological advancements emerged, so too did the requirements for bearings. This evolution paved the way for the refinement and optimization of 6206RS bearings, leading to their current state of excellence.

Throughout this exploration, we will uncover the transformative milestones and innovations that have shaped the evolution of 6206RS 30x62x16 Sealed Ball Bearings, their journey from conventional components to indispensable assets in modern mechanical engineering.

Historical Overview

6206RS 30x62x16 Sealed Ball Bearings have a rich history that spans decades, marked by significant milestones and advancements in mechanical engineering. Let's embark on a journey to explore the origins and evolution of these precision components.

|

Origins and Early Applications |

The story of 6206RS bearings begins with the need for reliable and efficient components to support various machinery and equipment. In the early days of mechanical engineering, bearings played a crucial role in reducing friction and enabling smooth motion in rotating parts. The introduction of sealed ball bearings, such as the 6206RS variant, represented a significant advancement, offering improved protection against contaminants and extending the lifespan of machinery. |

|

Milestones in Evolution |

Over the years, 6206RS bearings have undergone continuous refinement and enhancement to meet the evolving demands of industrial applications. Milestones in their evolution include advancements in materials, manufacturing techniques, and design optimization. For example, the adoption of high-quality steel alloys and advanced sealing technologies has significantly enhanced the durability and performance of 6206RS bearings, allowing them to operate efficiently in demanding environments. |

|

Key Advancements |

Several key advancements have propelled the evolution of 6206RS 30x62x16 Sealed Ball Bearings. These include the development of precision machining techniques, which enable tighter tolerances and smoother surface finishes, resulting in reduced friction and improved efficiency. Additionally, innovations in lubrication systems have contributed to extending the service life of bearings, ensuring reliable performance over extended periods. |

As we delve deeper into the historical overview of 6206RS bearings, it becomes evident that their evolution has been characterized by a relentless pursuit of excellence and innovation. From their humble beginnings to their current state of mastery, these bearings continue to set the standard for performance and reliability in mechanical engineering applications.

Technological Innovations

6206RS 30x62x16 Sealed Ball Bearings have witnessed remarkable advancements in technology, shaping their evolution and enhancing their performance across various applications. we delve into the latest technological innovations that have propelled the development of these precision components, revolutionizing their functionality and applications.

Integration of Advanced Materials

One of the key areas of innovation in 6206RS bearings is the integration of advanced materials. Manufacturers have increasingly turned to high-quality steel alloys and ceramics to improve bearing strength, durability, and resistance to wear and corrosion. These advanced materials not only enhance the overall performance of the bearings but also extend their service life, reducing maintenance requirements and downtime in industrial settings.

Precision Manufacturing Techniques

Technological advancements in precision manufacturing techniques have significantly contributed to the evolution of 6206RS bearings. Modern machining processes, such as computer numerical control (CNC) machining and laser cutting, enable the production of bearings with tighter tolerances and smoother surface finishes. This results in reduced friction, improved efficiency, and enhanced reliability, especially in high-speed and high-load applications.

Enhanced Sealing Technologies

Sealing technologies play a crucial role in protecting 6206RS bearings from contaminants and moisture, thereby extending their lifespan and maintaining optimal performance. Recent innovations in sealing materials and designs have led to the development of more effective and durable seals, capable of withstanding harsh operating conditions. These advancements ensure that 6206RS bearings remain reliable and functional even in challenging environments, such as those with high temperatures or exposure to chemicals.

Application of Advanced Lubrication Systems

Proper lubrication is essential for the smooth operation and longevity of 6206RS bearings. In recent years, significant advancements have been made in lubrication systems, including the development of specialty lubricants and automated lubrication systems. These innovations optimize the distribution of lubricants within the bearing, reducing friction, minimizing wear, and preventing premature failure. As a result, 6206RS bearings can operate at peak performance levels for extended periods without the need for frequent maintenance.

In summary, technological innovations continue to drive the evolution of 6206RS 30x62x16 Sealed Ball Bearings, enhancing their functionality, reliability, and versatility across a wide range of applications. These advancements represent the ongoing commitment of manufacturers to push the boundaries of bearing technology, delivering solutions that meet the evolving needs of modern industries.

|

Brand |

Features |

Advantages |

Disadvantages |

|

SKF |

High-quality steel construction, superior sealing |

Enhanced durability, resistance to contamination |

Higher initial cost, limited availability |

|

FAG |

Robust design, advanced sealing technology |

Excellent performance in high-speed applications |

Slightly higher friction, premium pricing |

|

NTN |

Precision engineering, innovative lubrication system |

Consistent performance, reduced maintenance needs |

Limited product range, higher upfront cost |

|

NSK |

Corrosion-resistant coatings, extensive product line |

Extended lifespan, suitability for harsh environments |

Higher pricing, limited availability |

|

Timken |

High load capacity, precision manufacturing |

Exceptional durability, reliable performance |

Higher cost compared to some competitors |

Performance Metrics

6206RS 30x62x16 Sealed Ball Bearings are renowned for their exceptional performance across various industrial applications.we delve into the critical performance metrics associated with these bearings, examining the factors that influence their efficiency, reliability, and overall effectiveness.

Load Capacity

Load capacity is a fundamental performance metric for 6206RS bearings, indicating the maximum load they can support without experiencing premature failure. It encompasses both radial and axial loads, with manufacturers providing load ratings for different bearing configurations. Factors such as bearing material, design, and internal geometry play crucial roles in determining load capacity, ensuring that the bearings can withstand the forces exerted upon them during operation.

Speed Ratings

Speed ratings define the maximum rotational speed at which 6206RS bearings can operate reliably without experiencing excessive heat generation or premature wear. These ratings are influenced by various factors, including bearing size, lubrication, and cage design. High-quality bearings are engineered to deliver consistent performance across a wide range of operating speeds, enabling them to meet the demands of diverse industrial applications while maintaining optimal efficiency and durability.

Precision

Precision is another essential performance metric for 6206RS bearings, particularly in applications where tight tolerances and smooth operation are critical. Precision bearings are manufactured to stringent specifications, ensuring minimal runout and accurate alignment of bearing components. This precision enhances the overall efficiency of machinery and equipment, reducing vibration, noise, and energy consumption while maximizing productivity and performance.

Sealing Efficiency

Efficient sealing is vital for protecting 6206RS bearings from contaminants, moisture, and other environmental factors that could compromise their performance and longevity. High-quality seals prevent ingress of dirt, dust, and liquids into the bearing cavity, minimizing the risk of corrosion, abrasion, and premature failure. Advanced sealing technologies, such as labyrinth seals and rubber shields, enhance the sealing efficiency of 6206RS bearings, ensuring reliable operation even in harsh operating conditions.

In summary, 6206RS 30x62x16 Sealed Ball Bearings exhibit exceptional performance across various metrics, including load capacity, speed ratings, precision, and sealing efficiency. By understanding and optimizing these performance factors, engineers and manufacturers can harness the full potential of these bearings, achieving superior performance and reliability in their mechanical systems.

Durability and Reliability

6206RS 30x62x16 Sealed Ball Bearings are esteemed for their unparalleled durability and reliability in various mechanical applications. we delve into the critical factors that contribute to the exceptional performance and longevity of these bearings, supported by insightful case studies and real-world examples.

Bearing Materials and Construction

The durability of 6206RS bearings is profoundly influenced by the materials used in their construction. High-quality bearing materials, such as chrome steel, stainless steel, or ceramic, exhibit excellent resistance to wear, corrosion, and fatigue, ensuring prolonged service life even under demanding operating conditions. Moreover, advanced manufacturing techniques, including precision machining and heat treatment processes, optimize the structural integrity and performance of these bearings, further enhancing their durability and reliability.

Sealing Technology

Effective sealing is paramount for maintaining the integrity of 6206RS bearings and safeguarding them against contaminants, moisture, and other environmental hazards. Innovative sealing technologies, such as rubber seals or metal shields, provide superior protection, preventing ingress of particles and fluids into the bearing assembly. This enhances the longevity and reliability of the bearings, reducing the risk of premature failure and minimizing maintenance requirements, especially in harsh or abrasive environments.

Lubrication Systems

Proper lubrication is essential for maximizing the durability and reliability of 6206RS bearings by reducing friction, dissipating heat, and preventing wear. Lubricants, such as grease or oil, create a protective film between bearing surfaces, minimizing metal-to-metal contact and extending bearing life. Additionally, automated lubrication systems or centralized lubrication systems ensure consistent and optimal lubrication levels, enhancing the performance and longevity of the bearings in various industrial applications.

Case Studies and Real-World Examples

To illustrate the durability and reliability of 6206RS bearings, we present compelling case studies and real-world examples highlighting their performance in diverse applications. From heavy machinery and automotive systems to precision instruments and industrial equipment, these bearings consistently deliver exceptional performance, longevity, and reliability, earning the trust and confidence of engineers, manufacturers, and end-users worldwide.

In summary, 6206RS 30x62x16 Sealed Ball Bearings epitomize durability and reliability in mechanical engineering, thanks to their robust construction, advanced sealing technology, and optimized lubrication systems. Through meticulous design, rigorous testing, and continuous innovation, these bearings continue to set new standards for performance and reliability, empowering industries to achieve greater efficiency, productivity, and sustainability.

Future Trends and Innovations

In the realm of 6206RS 30x62x16 Sealed Ball Bearings, the pursuit of innovation is relentless, driven by the ever-evolving needs of industries and advancements in engineering technology. This explores the exciting future trends and potential innovations that are poised to shape the evolution of these bearings.

|

Nanotechnology Integration |

One of the most promising avenues for future innovation in 6206RS bearings lies in the integration of nanotechnology. By leveraging nanoscale materials and structures, engineers can enhance the performance and durability of bearings, improving load capacity, reducing friction, and extending service life. Nanocoatings and nanoparticles infused into bearing surfaces offer superior wear resistance and friction reduction, paving the way for more efficient and reliable bearing solutions. |

|

Smart Bearings and Predictive Maintenance |

With the rise of the Internet of Things (IoT) and Industry 4.0, the concept of smart bearings equipped with sensors and connectivity features is gaining traction. These advanced bearings can monitor various performance parameters in real-time, such as temperature, vibration, and lubrication condition, enabling predictive maintenance strategies. By leveraging data analytics and machine learning algorithms, operators can anticipate potential issues, schedule maintenance proactively, and optimize the performance and longevity of 6206RS bearings, leading to reduced downtime and lower maintenance costs. |

|

Sustainable and Eco-Friendly Materials

|

In response to growing environmental concerns, the future of 6206RS bearings is likely to see a shift towards sustainable and eco-friendly materials. Engineers are exploring alternative materials derived from renewable sources or recycled materials, reducing the environmental footprint of bearing production and disposal. Additionally, advancements in manufacturing processes, such as additive manufacturing or 3D printing, offer opportunities to optimize material usage, minimize waste, and create more environmentally friendly bearing solutions. |

|

Advanced Coatings and Surface Treatments |

Surface engineering technologies, including advanced coatings and surface treatments, play a crucial role in enhancing the performance and durability of 6206RS bearings. Future innovations in this area may include the development of self-lubricating coatings, diamond-like carbon (DLC) coatings for improved wear resistance, and nanocomposite surface treatments for enhanced tribological properties. These innovations will enable bearings to operate more efficiently in demanding applications, withstand harsh environments, and extend maintenance intervals. |

In conclusion, the future of 6206RS 30x62x16 Sealed Ball Bearings is brimming with exciting possibilities, driven by advancements in nanotechnology, IoT connectivity, sustainable materials, and surface engineering. By embracing these future trends and innovations, engineers and manufacturers can continue to push the boundaries of performance, reliability, and sustainability, ushering in a new era of excellence in mechanical engineering.

Conclusion

In conclusion, the journey through the evolution of 6206RS 30x62x16 Sealed Ball Bearings unveils a rich tapestry of advancements, innovations, and achievements that have shaped the landscape of mechanical engineering.

From their humble origins to their current state-of-the-art designs, these bearings have undergone a remarkable transformation driven by relentless innovation and engineering excellence. The historical overview provided insights into the origins of these bearings, tracing their evolution from simple mechanical components to sophisticated precision instruments.

As we delved into the technological innovations, it became evident that the future of 6206RS bearings is brimming with promise. Nanotechnology integration, smart bearings, sustainable materials, and advanced coatings represent just a few of the avenues for future development, promising enhanced performance, reliability, and sustainability.

Furthermore, the examination of performance metrics underscored the critical importance of factors such as load capacity, speed ratings, and precision in determining the suitability of 6206RS bearings for various applications. These metrics serve as benchmarks for evaluating the performance and quality of bearings, ensuring optimal functionality and longevity.

The discussion on durability and reliability highlighted the robustness and resilience of 6206RS bearings, backed by real-world case studies and examples. These bearings have proven their mettle in demanding environments, demonstrating exceptional durability and reliability under challenging conditions.

Looking ahead, the future trends and innovations presented a glimpse into the exciting possibilities that lie ahead for 6206RS bearings. From nanotechnology to predictive maintenance, sustainable materials to advanced coatings, the future is ripe with opportunities to push the boundaries of performance and reliability.

In summary, 6206RS 30x62x16 Sealed Ball Bearings stand as a testament to the ingenuity, innovation, and engineering prowess that define modern mechanical engineering. Their evolution is a testament to the tireless pursuit of excellence and the relentless drive to master performance in the ever-changing landscape of mechanical systems. As we embark on the next phase of innovation, these bearings will continue to play a pivotal role in shaping the future of mechanical engineering, underpinning the reliability, efficiency, and performance of a wide range of industrial applications.

FAQs: Common Questions About 6206RS 30x62x16 Sealed Ball Bearings

we address some common questions and concerns regarding 6206RS 30x62x16 Sealed Ball Bearings, providing clarity and insights into their functionality, applications, and benefits.

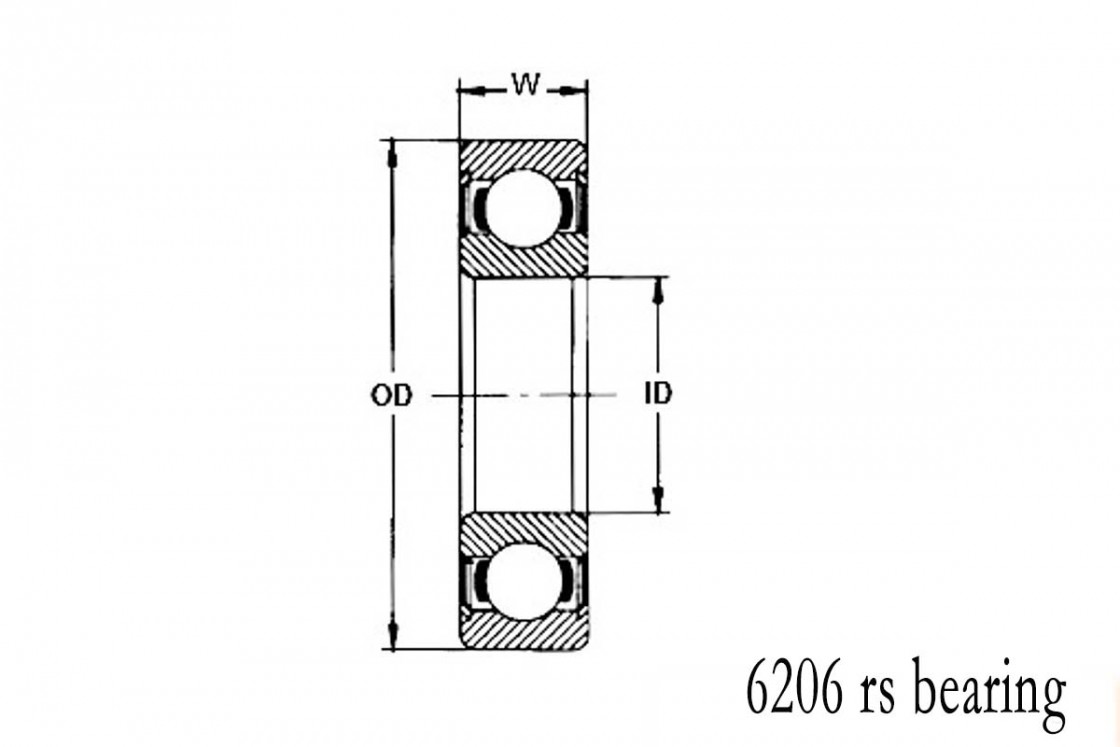

What are 6206RS 30x62x16 Sealed Ball Bearings?

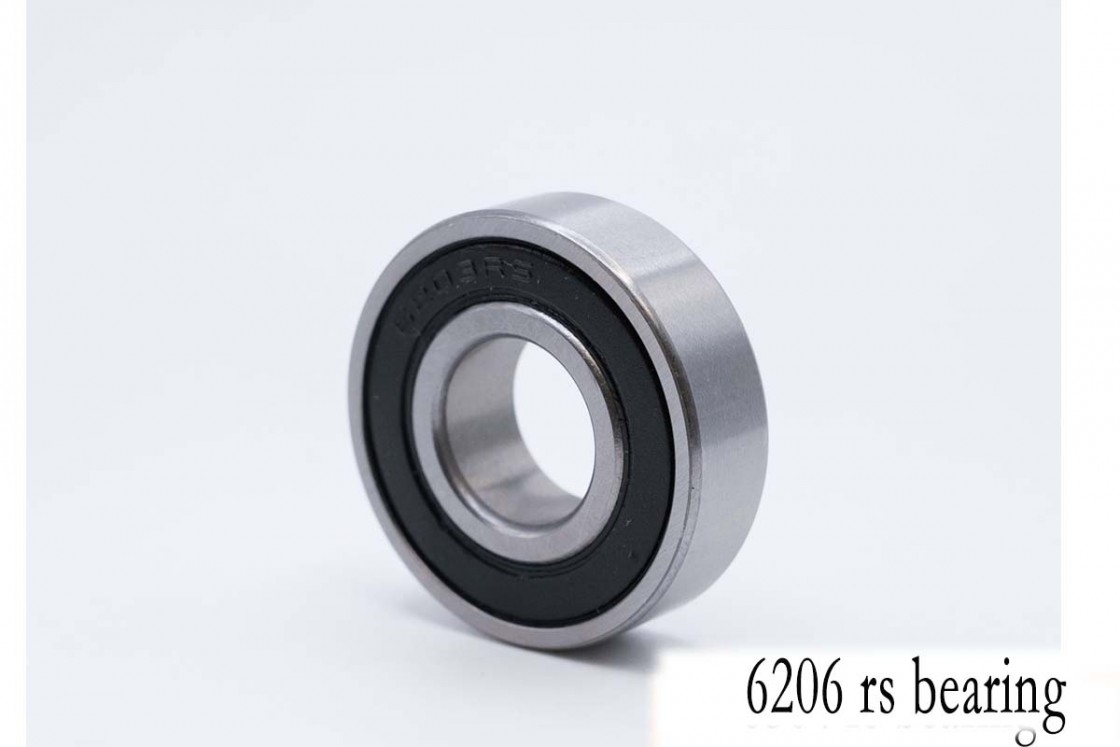

- These bearings are precision-engineered components designed to facilitate smooth rotational motion while maintaining a seal to prevent contamination and retain lubrication. The designation "6206RS" indicates the bearing's dimensions (30x62x16) and its sealed configuration.

What are the key features of 6206RS bearings?

- Key features include their sealed design, which protects against contaminants and retains lubrication, ensuring long-lasting performance. Additionally, these bearings are precision-manufactured to tight tolerances, resulting in smooth operation and reduced friction.

What are the applications of 6206RS bearings?

- 6206RS bearings find applications in a wide range of industries, including automotive, aerospace, manufacturing, and machinery. They are commonly used in electric motors, pumps, gearboxes, and conveyor systems, among others, where smooth and reliable rotational motion is essential.

How do 6206RS bearings contribute to performance optimization?

- By providing smooth and reliable rotational motion, 6206RS bearings contribute to the overall efficiency and performance of mechanical systems. Their sealed design ensures minimal maintenance requirements and prolonged service life, enhancing operational reliability and reducing downtime.

What factors should be considered when selecting 6206RS bearings?

- When selecting 6206RS bearings, factors such as load capacity, speed ratings, environmental conditions, and compatibility with lubricants should be taken into account. It's essential to choose bearings that meet the specific requirements of the application to ensure optimal performance and longevity.

How can I ensure the proper maintenance of 6206RS bearings?

- Proper maintenance of 6206RS bearings involves periodic inspection, lubrication, and replacement as needed. Regular monitoring of bearing condition, temperature, and vibration levels can help identify potential issues early and prevent costly failures.

What are the advantages of using 6206RS bearings over alternatives?

- The advantages of 6206RS bearings include their sealed design, which offers superior protection against contamination and extends bearing life. Additionally, their precision manufacturing ensures consistent performance and reduced friction, leading to enhanced efficiency and reliability.

By addressing these common questions, we aim to provide a comprehensive understanding of 6206RS 30x62x16 Sealed Ball Bearings and their significance in various industrial applications.

232/500 KCW33+H32/500 SKF Spherical Roller Bearings

232/500 KCW33+H32/500 SKF Spherical Roller Bearings 23128-E1A-M FAG Spherical Roller Bearings

23128-E1A-M FAG Spherical Roller Bearings